B2, B3, B4 smeid stielen ballen

Skilje ús foar ynformaasje:Tel: +86-18973821771

Oersicht:

| Type | Forged stielen bal, Forged stielen media bal | ||

| Spesifikaasje | 45#, 50Mn, 60Mn, 65Mn, B2, B3, BL, BG | ||

| Oarsprong | Sina | HS Koade | 84749000 |

| Betingst | Nij | Tapasbere yndustry | Enerzjy & Mining |

| Machine Type | Ball Mill Liner | Certification | ISO 9001:2008 |

| Main Materialen | Mn13Cr2, Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Ferwurkjen Type | Casting | Impact Toughness | >12ak.J/Cm^2 |

| Casting Ynspeksje | spektrometer, hurdens tester, mikroskoop, drop tester, impact tester, laser cutting machine, ensfh | ||

| Ferfier Package | Stalen trommels en fleksibele kontenerzakken | Garandearje | Itselde as Original |

| Kwaliteit | Heech nivo | Ûnderfining | Mear as 30 jier |

Gietmateriaal gemyske gearstalling:

| Materiaal | C | Mn | Si | Cr | P/S |

| 45# | 0,42-0,48 | 0,50-0,80 | 0,17-0,37 | ≤ 0,25 | ≤ 0.035 |

| 50 Mn | 0,48-0,56 | 0,70-1,0 | 0,17-0,37 | ≤ 0,25 | ≤ 0.035 |

| 60 Mn | 0,57-0,65 | 0,70-1,0 | 0,17-0,37 | ≤ 0,25 | ≤ 0.035 |

| 65Mn | 0,62-0,70 | 0,90-1,20 | 0,17-0,37 | ≤ 0,25 | ≤ 0,030 |

| B2 | 0,75-0,85 | 0,70-0,90 | 0,17-0,37 | 0,40-0,60 | ≤ 0,030 |

| B3 | 0,55-0,65 | 0,75-0,90 | 0,20-0,37 | 0,85-1,20 | ≤ 0,030 |

| B4 | 0,58-0,66 | 0,65-0,80 | 1,60-1,90 | 0,70-0,90 | ≤ 0,030 |

| B6 | 0.97-1.03 | 1.00-1.10 | 0.20-0.30 | 0,50-0,60 | ≤ 0.025 |

Grinding media smeid stielen ballen Mechanical Propety

| Namme | Impact Wearde AK.J/cm2 | Droptest (sm) | Hurdens | |||||

| Ф25-50 (1"-2") | Ф60-90 (2.5"-3.5") | Ф100-150 (4"-6") | ||||||

| Oerflak | Kearn | Oerflak | Kearn | Oerflak | Kearn | |||

| 45# | ≥12 | ≥15000 | ≥55 | ≥38 | ≥50 | ≥35 | ≥45 | ≥25 |

| 50 Mn | ≥12 | ≥15000 | ≥56 | ≥40 | ≥56 | ≥35 | ≥50 | ≥30 |

| 60 Mn | ≥12 | ≥15000 | ≥58 | ≥45 | ≥58 | ≥38 | ≥52 | ≥35 |

| 65Mn | ≥12 | ≥15000 | ≥60 | ≥52 | ≥60 | ≥42 | ≥53 | ≥36 |

| B2 | ≥12 | ≥15000 | ≥60 | ≥60 | ≥60 | ≥54 | ≥55 | ≥48 |

| B3 | ≥12 | ≥15000 | ≥60 | ≥60 | ≥60 | ≥54 | ≥58 | ≥53 |

| BL | ≥12 | ≥15000 | ≥60 | ≥60 | ≥60 | ≥54 | ≥58 | ≥55 |

| BG | ≥12 | ≥15000 | ≥60 | ≥60 | ≥60 | ≥60 | ≥60 | ≥60 |

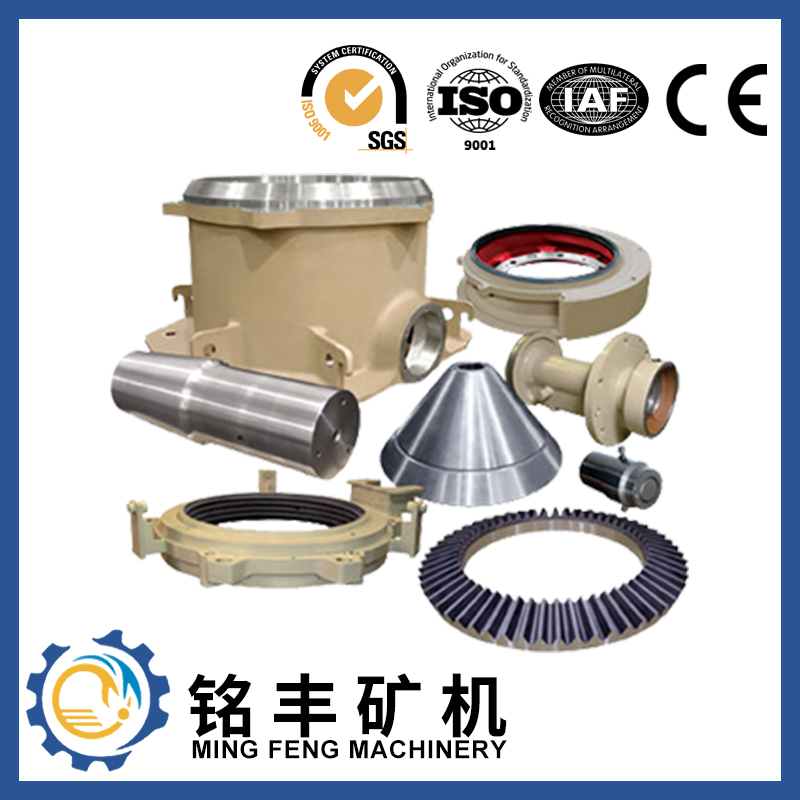

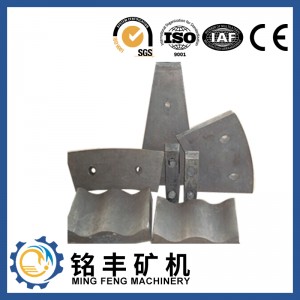

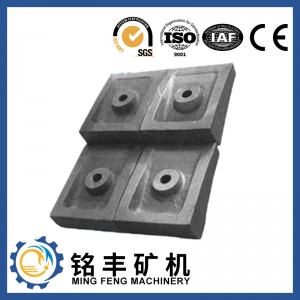

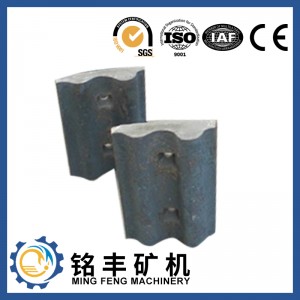

Crusher Parts:

Wy hawwe presys masjineare ferfangende crusher-ûnderdielen ynklusyf kop, bowls, haadas, socketliner, socket, eksintrike bus, holle bushings, gear, countershaft, countershaft bushing, countershaft húsfesting, mainframe seat liner en mear, wy kinne jo hiele masine stypje foar meganyske reserve dielen.

Wêrom kieze ús?

1.30 jier produksjeûnderfining, 6 jier ûnderfining yn bûtenlânske hannel

2.Strikte kwaliteitskontrôle, Eigen laboratoarium

3.ISO9001:2008, BUREAU VERITAS

Skriuw jo berjocht hjir en stjoer it nei ús

HOT-SALE PRODUCT

Kwaliteit earst, feiligens garandearre