Hege mangaan stielen cone crusher dielen foar mienskiplik, Symons

Basisynformaasje

Model NO.: MF of oanpast

Casting Form Materiaal: Hout of Foam

Casting Form Usage Count: Wegwerp

Oerflak Roughness: Ra6.3

Standert: AISI

Grutte: Oanpast

Applikaasje: Cone Crusher

Produkt foardiel: Duorsum en stabyl

Handelsmerk: FENGWEI

Spesifikaasje: ISO

HS Koade: 84749000

Casting Metoade: Sand Casting of Lost Foam Casting

Casting Metal: Cast Steel

Oerflak behanneling: Sand Blast

Machtigingsformulier Tolerânsje: +/- 0,15 mm

Sertifisearring: SGS, ISO 9001:2008

Kleur: Oanpast

Ynhâld fan Mn: 13%, 18%, 20%, 24%

OEM-tsjinst: Ja

Ferfierpakket: houten koffer as pallet, geskikt foar seeferfier.

Oarsprong: Hunan

produkt Omskriuwing

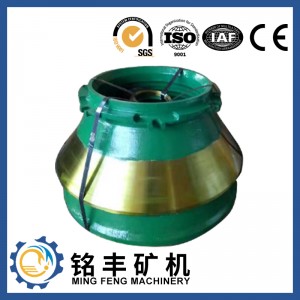

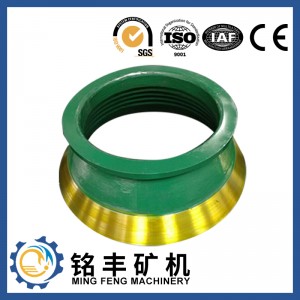

Hege Mangaan Steel Cone Crusher Parts foar gewoane, Symons

Fengwei is in profesjonele fabrikant fan slijtagedielen foar crusher, wy leverje OEM-tsjinst foar in protte ferneamde Crusher-merken, ynklusyf:

mienskiplik |Pegson |Lokomo |Svedala |Allis Chalmers |Symons |gewoan.|Fintec |Finlay |Exec |Kue-Ken/Brown Lennox |LOKOMO |Telsmith, etc

Oanpast fersyk is beskikber, wy akseptearje de stekproefferwurking of tekenferwurking.

1. Cone crusher dielen wichtichste Materiaal:

Heech mangaan stiel: Mn13%, Mn18%, Mn22%, Mn24%;

Heech chromium izer: Cr20, Cr24 up

Koalstof stiel

2. Hege Mangan Casting Materiaal Chemical Composition (%)

Koade ElemCMnSiCrMoPS

ZGMn13-21.0-1.4512.5-13.50.30-1.00.02-≤ 0.09≤ 0.04

ZGMn18-21.0-1.3517.5-18.50.30-1.00.02-≤ 0.09≤ 0.04

3. Mear crusher-ûnderdielen:

3.1 Kaakbreker dielen:

Jaw plaat (kaak liner), toggle plaat, up guard plaat, down guard plaat, set oanpassing, spanning stang, toggle pakking, spring, spanning rod, eksintrike as, ein cover, blok, bewegende kaak, frame, spring, bout en moeren , waskmasine.

3.2 Impact crusher dielen:

Blow bar (platte hammer), oanpassing bar, impact plaat, liner plaat, frame (impact rack), cover, , bouten, moeren, washer, ensfh

3.3 Hammer crusher dielen

Hammerkop, linerplaat, bout, moeren, washer

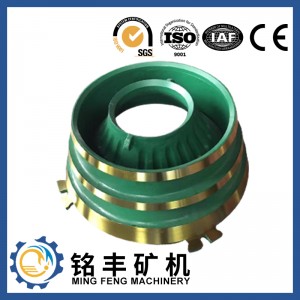

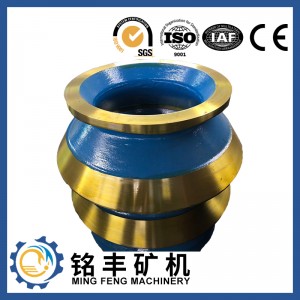

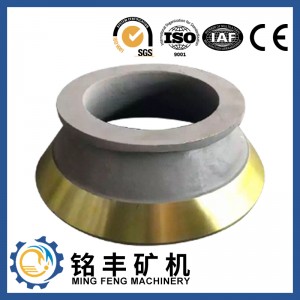

3.4 Cone crusher dielen:

Hege Manganess Casting Materiaal gemyske gearstalling

| Materiaal Code | C | Mn | Si | Cr | P | S |

| ZGMn13Cr2 | C: 0,9-1,3 | Mn: 11.0-14.0 | Si: 0.3-1.0 | Cr:1,5-2,5 | P:≤0,06 | S:≤0,04 |

| ZGMn18Cr2 | C:1,1-1,5 | Mn: 16.5-19.0 | Si: ≤0.8 | Cr:1,5-2,5 | P:≤0,07 | S:≤0,04 |

| ZGMn22Cr2 | C:1.1-1.4 | Mn:20-24 | Si: ≤0.8 | Cr:1,5-2,5 | P:≤0,07 | S:≤0. |

Fengwei Full Range foar Crusher Wear Liners & Parts

| Crusher Wear Liners & Parts | |

| Gyratory Crushers | CS420/S2800, CS430/S3800, CS440/S4800, CS660/S6800 |

| Jaw Crushers | JM907 JM1107 JM1108 KM1206 JM1208 JM1211 JM1312 JM1511 JM1513 |

| Common Crusher Wear Liners & Parts | |

| Common Cone Crushers | HP100,HP200,HP300,HP400,HP4,HP500,HP700,HP800 |

| Common Gyratory Crushers | GP100, GP300, GP500 |

| Common Jaw Crushers | C63 C80 C100 C110 C125 C140 C160 C200 |

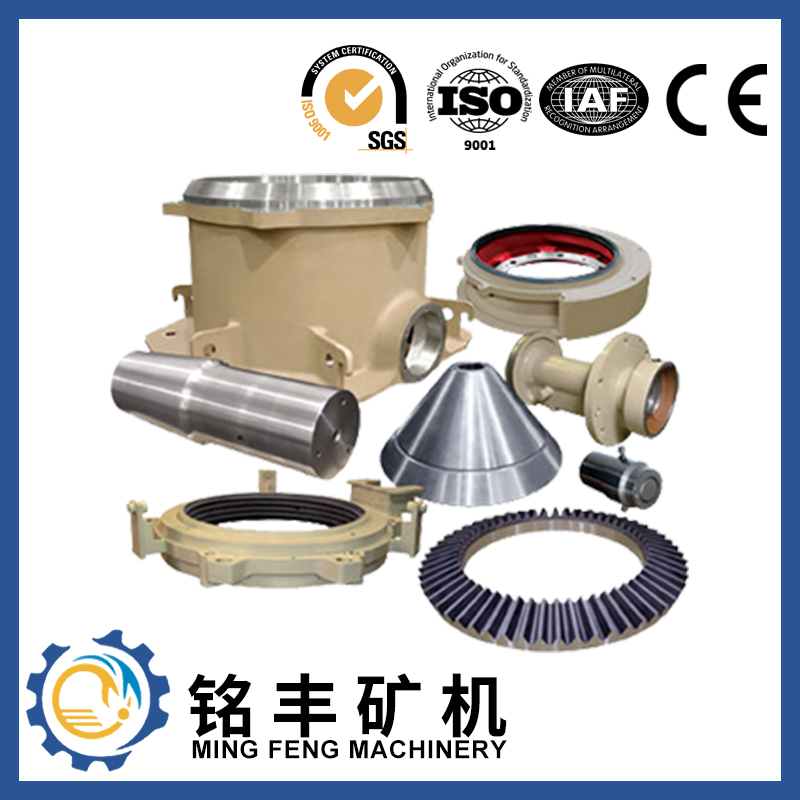

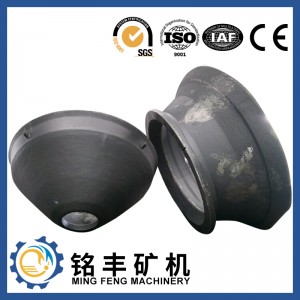

Cone Crusher Parts:

Wy hawwe presys masjineare ferfangende crusher-ûnderdielen ynklusyf kop, bowls, haadas, socketliner, socket, eksintrike bus, holle bushings, gear, countershaft, countershaft bushing, countershaft húsfesting, mainframe seat liner en mear, wy kinne jo hiele masine stypje foar meganyske reserve dielen.

Wêrom kieze ús?

1.30 jier produksjeûnderfining, 6 jier ûnderfining yn bûtenlânske hannel

2.Strikte kwaliteitskontrôle, Eigen laboratoarium

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Kwaliteit earst, feiligens garandearre